Build Diary 27-August-05

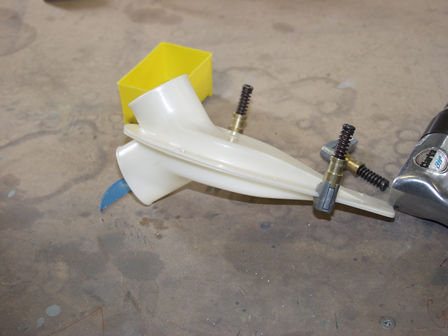

Worked on fresh air vents, canopy latch, control rod, and painted parts.

I am really wizzing through these odd jobs.....

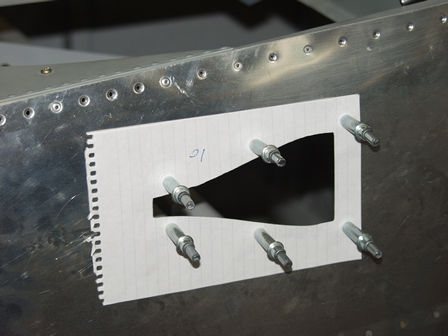

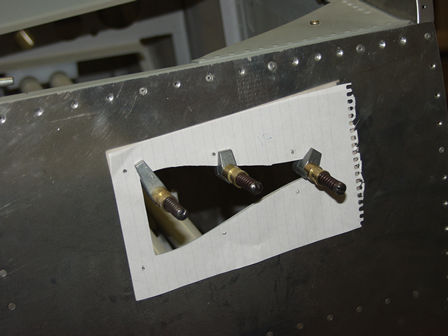

First I aligned the inlet and marked were the fixing holes are to go.

Note: Vans say rivets, some people glue/bond or screw fix this. I am going to rivet as per Vans instructions.

Images & text copyright GAPilot & Go-7. This mail is not connected to Vans Aircraft Inc. The contents of this site is the opinion of the author, not Vans Aircarft, PFA, CAA or FAA. Please check all information is correct before you act upon it.

Previous

page

Previous

page