Build Diary 03/04-January-06

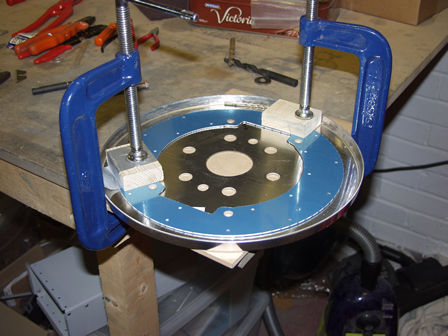

Connecting sensors to AF-2500. Fitting aerial leads for transponder and radio. Starting work on cowl - spinner, with the intention of fitting the spinner to align the cowl. BUT I discovered a problem with my plan. I am fitting a CS prop, the spinner fits to the prop. Rather than the plate fixing to the flywheel. I don't have my prop yet - so I can't fit the spinner thus I can't fit the cowl

Images & text copyright GAPilot & Go-7. This mail is not connected to Vans Aircraft Inc. The contents of this site is the opinion of the author, not Vans Aircarft, PFA, CAA or FAA. Please check all information is correct before you act upon it.

Previous

page

Previous

page