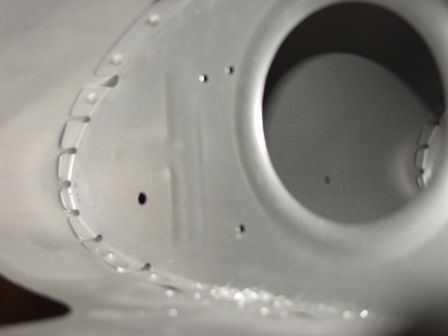

Here I am having just completed the first engine run.

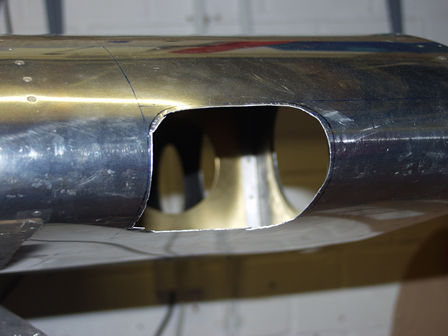

Wings on about to roll out of the

hanger for first engine start.

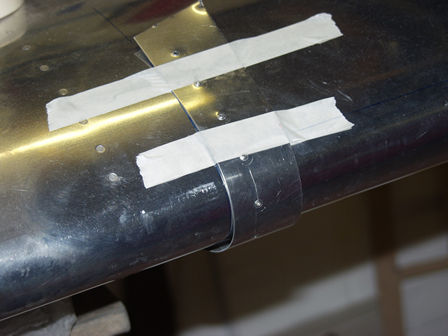

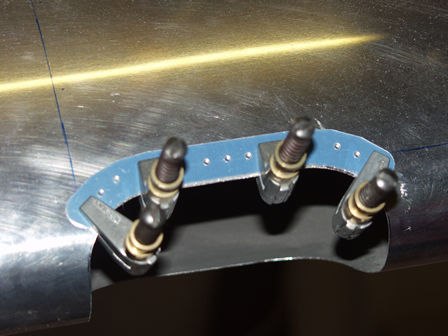

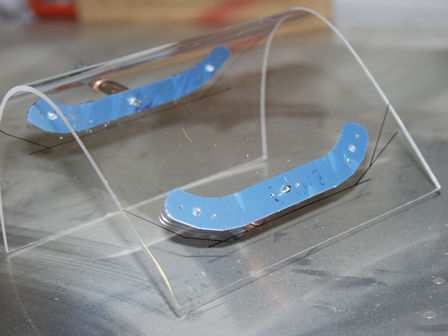

The way to fit split pins properly -

Aviation Standards!!

Roberts RV6, we stop for fuel on

the way to the RV fly-in at Colmar.

First Test flight of G-OVII my RV7 carried out by Bob Cole at Thruxton on 18th November 2006.