Here I am having just completed the first engine run.

Wings on about to roll out of the

hanger for first engine start.

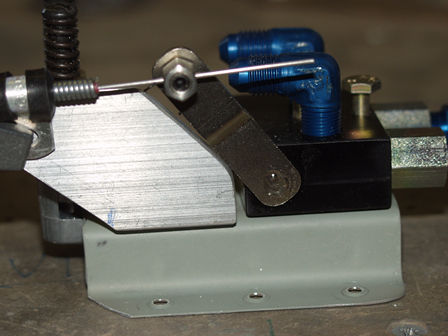

The way to fit split pins properly -

Aviation Standards!!

Roberts RV6, we stop for fuel on

the way to the RV fly-in at Colmar.

First Test flight of G-OVII my RV7 carried out by Bob Cole at Thruxton on 18th November 2006.

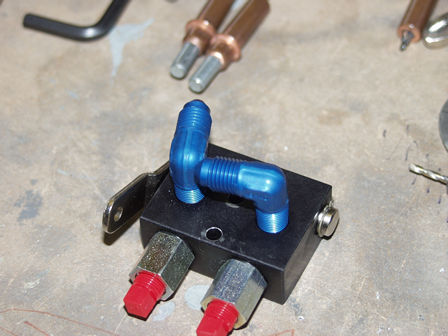

I have fitted the park brake on the firewall - low down - this is to ensure I can see it to service and check for leaks. I have seen some located higher up which would make it harder to maintain. Since fitting and testing the valve I have found it difficult to seal properly. I know another builder has similar problems with the brake servo.

UPDATE: These have caused problems with them leeking. i had to remove these angle fittings and reseal.