Build Diary 07/08/09-October-05

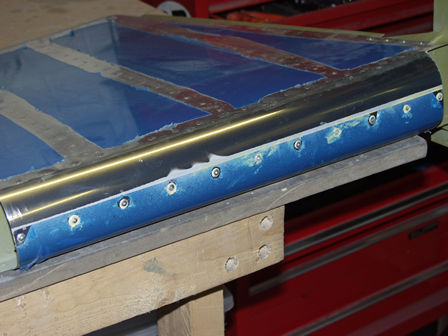

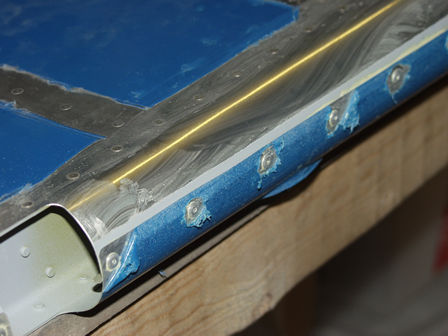

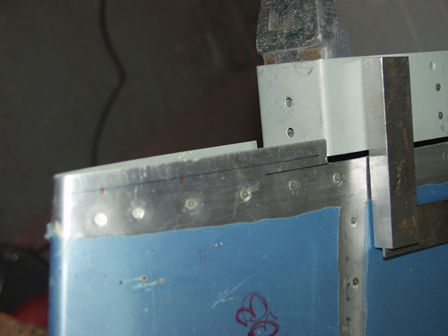

Friday evening, completed rudder leading edge.

Saturday,

just a few hours in the workshop. Most spent trying to find the rod ends to fit to the rudder.

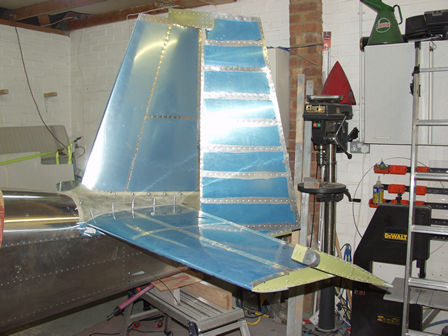

I finally found some so I could fit the rudder for the first time.

Sunday. Jo is away

today so I have spent most of the day working on the RV - just a quick trip to Popham in the

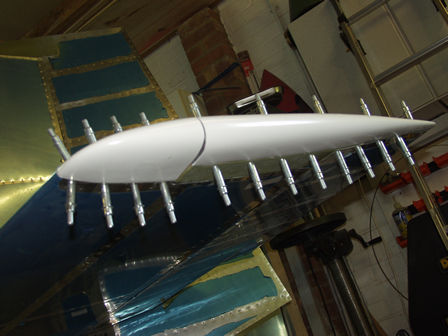

afternoon to look at RV's! I have managed to fit nearly all the fiberglass endcaps to the

empannage (Rudder, HS & Elevators). They need some filler to finish but its been a good days

work. I have heard some builders leave these as they are not much fun. I thought they went

quite well. ** RV7 needs to have the skin trimmed for the mass balance weight to fit, did give me a shock at first - thought I had done something wrong.

Images & text copyright GAPilot & Go-7. This mail is not connected to Vans Aircraft Inc. The contents of this site is the opinion of the author, not Vans Aircarft, PFA, CAA or FAA. Please check all information is correct before you act upon it.

Previous

page

Previous

page