Vans RV7 2005 Build Diary

After 20 months of building, G-OVII lifts off -

13:40 on 18th November 2006 - into the air for the first time. The

sight was incredible as almost two years of work came together. Read

all about it here.

21st November 2005

Checked all brake pedal lines. Planned Instrument circuit braker layout. Didn't

do much more it's 27F outside tonight - workshop is not much above that!!

9th November 2005 (Check)

Fitted left hub and wheel. It's really cold in the workshop this evening,

so I didn't do much more. Ordered the firewall forward kit from Vans

this evening.

31st October 2005

Spent this evening fitting nutplates, dimpling and deburring the instrument

subpanels and parts. Planned layout of circuit breakers on the instrument

panel.

I have been away from the project for a while, and collected some parts for

the RV wile visiting Florida. John has helped and collected my parcels

ready for my arrival. I even managed to collect the new Dynon D100 Electronic

Flight Information System.

6th September 2005

Repainted the cockpit footwell AGAIN. Yes, I was not happy with the results

last night so I have rubbed it all down this evening and re-painted

it again. So far it looks good, tomorrow morning will tell.5th September 2005

Repainted the cockpit footwell this evening.

1/2nd September 2005

Worked on instrument panel design, I got some MDF to mock up the panel. I

don't have the Dynon D100 yet so I don't want to cut the original panel.30/31st August 2005

Another big day - offered up the engine to the frame to see were the controls

may need to come through the firewall. All seems well so I have decided

to put the fuse on it's wheels.29th August 2005

Really big day engine arrived - Jade Air delivered my Superior IO-360

engine this morning.

Checked all brake pedal lines. Planned Instrument circuit braker layout. Didn't

do much more it's 27F outside tonight - workshop is not much above that!!

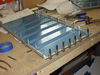

20th August 2005(Picture)

Started work on the firewall. Fitted batterybox, master and starter relay's.

Fitted various nutplates on firewall.

Decide to wait for the firewall forward kit to arrive from Vans before continuing

with the fuse work. I had been given a Duck Works landing light by another

builder and finally decided I would fit it.

Fitted left hub and wheel. It's really cold in the workshop this evening,

so I didn't do much more. Ordered the firewall forward kit from Vans

this evening.

Fitted brake pedal hydraulic lines.

Primer time - I have dismantled the rollbar, canopy and the rear fuse ready

for painting.

21st July 2005

Starting to think about the avionics. The panel layout and area behind needs

to be planned.18/19th July 2005

Dimpling the final rear skin, and prep ready to start spraying..

The rudder has some blind rivets that stand proud from the skin. It's bugged

me for a while, so this morning I decided I could not look at them any

longer.

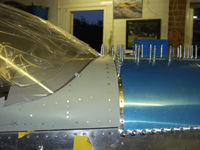

Finished cutting the rear window, made final trim. Started on canopy side

strips.

7th July 2005

Continued with re-enforcement.

15th June 2005

Cut the canopy release hole in the side of the fuse..

Went flying today and collected some extra nut plates from Robert, all fitted

by late afternoon.

Continued work on fitting HS and VS, trail wheel mount is ready to prime and

fit. Prep work for more priming. Jo came and took some pictures of me

working on the VS.

A good day in the workshop today, continued with fitting of the empannage.

Some work on the canopy mounts. Started making brackets to fit empannage.

Collected top coat paint for cockpit area.

Spraying front half of cockpit interior. Updated the Painting Page, bigger

pictures and added details about paint being used.

15th May 2005

Popham RV Fly-in. Got back and tidied workshop.

Right fuel tank bracket, and fuel tank breather.

Fitted right flap to wing.

A little work on the canopy release mech..

Fitting Fuel pump and filter housing in fuse.

Part of my order arrives from Vans.

18th April 2005

Continued work on flap.14-15th April 2005

Aileron hinges complete and riveted on wing.10th April 2005

Jo helped me get the left wing down (stored in roof of workshop) to start

work on it. 9th April 2005

Cleaned and tidied workshop.

Jo helps with a few more rivets on the wing.

Jo is fantastic. She arrived in the garage today, and asked if I wanted help

fitting the wing skin. Jo has never riveted so I gave her a quick lesson

and then we started on the wing skin. Jo did a great job taking lots

of care to ensure the job was done properly. The skin looks great. Thanks

Jo.

Riveted baggage floor. Also managed to fit a few wing rivets. Will hopfully

have some assistance at the weekend.

Painting.

26th March 2005

Deburring rollbar.

Starting the canopy rollover bar, making the brackets.

20th March 2005

Seat back brace. Canopy latch work on fuse.

Control rods.

Aileron rods & rod ends.

Fuse interior.

Pedal fitting.

Spent the evening painting (primer), wing panel, and seats.

28th February 2005

Made tunnel cover, prepared parts ready for spraying (Snowing outside workshop

this evening!).

Built seat brace, dismantled and de-burred seats ready for primer. Dismantled

brake pedals for priming.

I have decided to make the parts for the seats while I am wait for my right

wing to be inspected.

23rd February 2005

Deburred rudder pedals... .

Deburred rudder pedals, and reviewed parts for rudder assembly.

21st February 2005

Started drilling tail wheel bracket - WD-409. Too cold in the workshop came

in after 45mins (it's been snowing today).

Waiting for inspector to visit, so started on fuse - tail wheel.

Started work on right wing skin.

Aileron control rod.

15th February 2005

Worked on aileron control road, fitting the 4-12 rivets was difficult.

11th February 2005

Started to fit rivets to aileron gap fairing (W-724) .... they were not very

good so I removed them and decided to call it a night!!

Trial fitted W-721.

Constructed the aileron hinge bracket assembly.

Built jig for QB wings, put right wing in jig.

A really good full day in the workshop, I completed the left HS stabilizer

skin and cleco in the rear spar into place. Then back riveted both the

elevators ribs in.

2nd January 2005

Went flying in my Cessna 150 EV to North Weald.

Images & text copyright GAPilot & Go-7. This mail is not connected to Vans Aircraft Inc. The contents of this mail is the opinion of the author, not Vans Aircarft, PFA, CAA of FAA. Please check all information is correct before you act upon it.