Build Diary 11/12-November-05

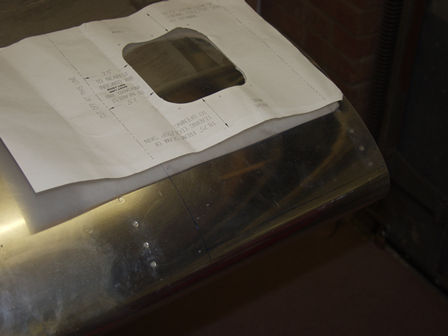

Friday - Jo (she is the best) helped put the left wing on the bench as I need to complete a few

small jobs on it. I had intentionally left these tasks as fill in jobs while waiting on something else - hence I have decide

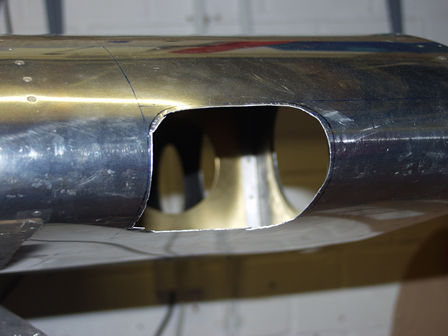

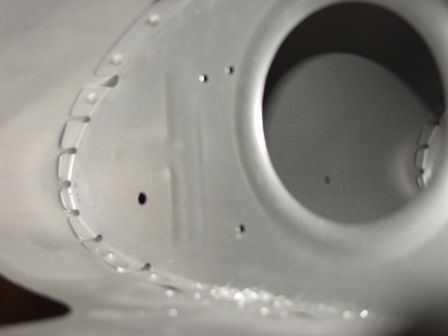

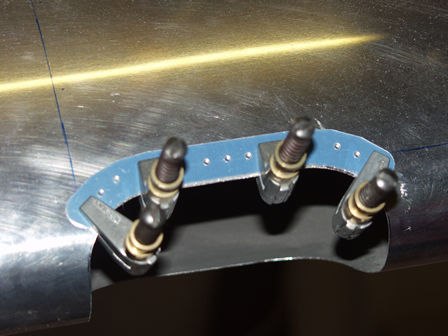

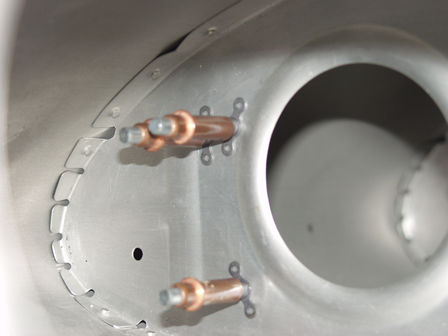

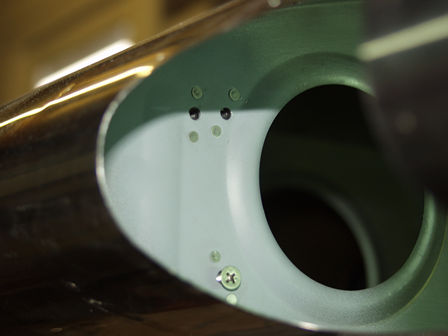

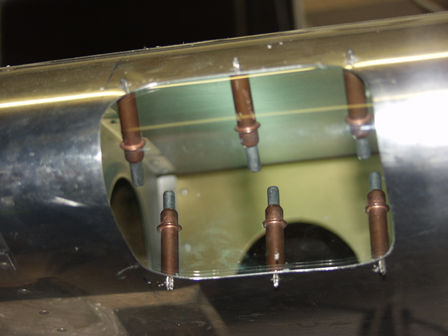

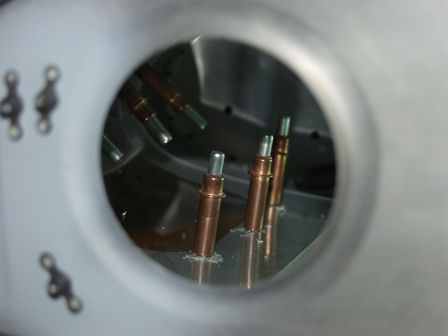

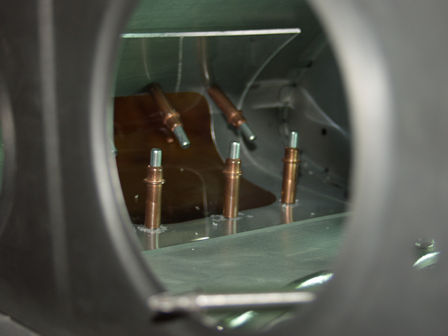

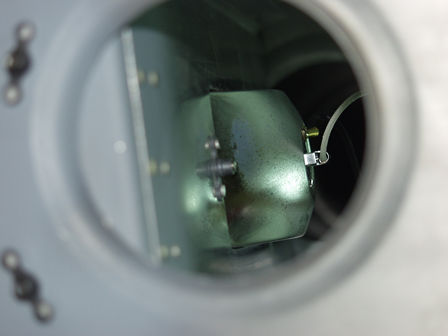

to wait for the firewall forward kit to arrive from Vans before continuing with the fuse work. I had been given a Duck Works

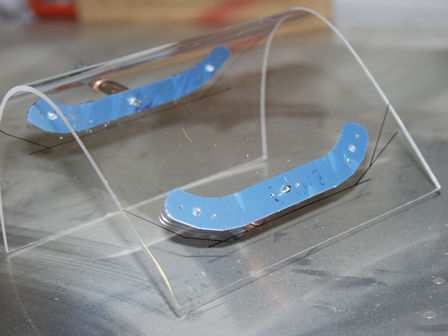

landing light by another builder and finally decided I would fit it. Vans have brought out a landing light kit to fit in the

wing tips, but it appears to not fit well with the strobes in the tip as well.

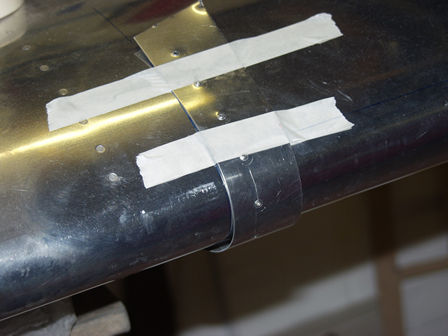

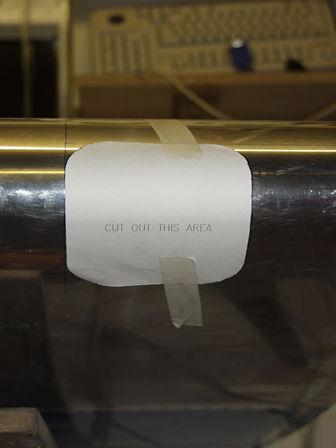

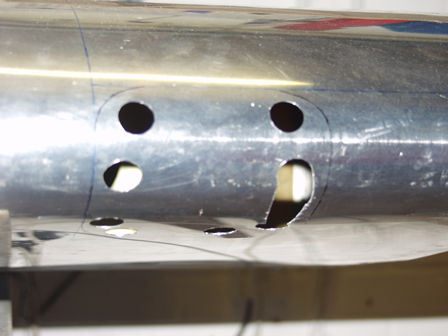

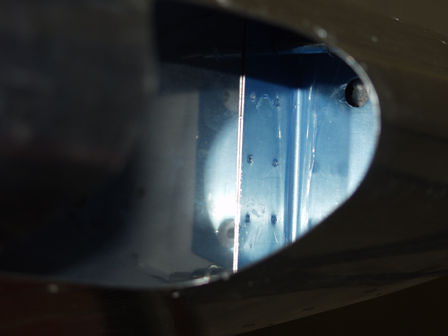

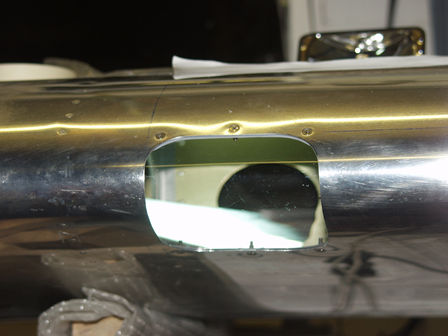

Saturday, I finally plucked up the

courage to drill into my wing - It had to go right because the damage would be very hard to correct!

UPDATE: OR I could as I did! Remove this pitot line and fit fully flexible pipe from pitot to instrument panel.

Images & text copyright GAPilot & Go-7. This mail is not connected to Vans Aircraft Inc. The contents of this site is the opinion of the author, not Vans Aircarft, PFA, CAA or FAA. Please check all information is correct before you act upon it.

Previous

page

Previous

page