Fitting an Advanced AF-2500 Engine Monitor to Vans

RV7 - Flap Position Sensor.

The Advanced AF-2500 monitors all the engine parameters

- Manifold Pressure, RPM, Oil Pressure Oil Temperature, Fuel Pressure,

Fuel flow, fuel tank levels (in flight and on the ground for tail

wheel a/c), Amps, Voltage, EGT & CHT on all 4 cylinders (also

available for 6)and some other aircarft parameters - Flap position,

Trim positions and user configured.

Flap Position Sensor.

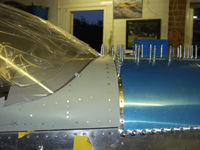

I have used a Ray Allen resistor/sensor to send the flap position information

to the Advanced analogue unit. It is connected to the flap control arm

via an 11inch rod/wire. One end is connected to the flap arm with a

P connector the other is through the hole in the sensor arm. The arm

is quite thin and flexible so it will never jam the flap arm, it would

just bend!I fitted a number of P clips to ensure the flap motor and sensor wires were held in place.

Ray Allen Position Sensor - POS12

The rod/wire is bent at 90 degrees and locates in the hole on the sensor (the

sensor is supplied with the hole in). Not shown in the picture to hold

the wire in place I used the inside of an electrical connector on the

end of the wire (I will find a picture showing this).One thing to note about the sensor mounting - The mount hole on the arm side, cannot have the head of a bold/screw or nut as this will get in the way of the arm. I attached the sensor with #6 screws with the heads on the rear of the sensor self tapping into the plastic of the sensor.