Wings on about to roll out of the

hanger for first engine start.

Roberts RV6, we stop for fuel on

the way to the RV fly-in at Colmar.

The way to fit split pins properly -

Aviation Standards!!

First Test flight of G-OVII my RV7 carried out by Bob Cole at Thruxton

on 18th November 2006.

Here I am having just completed the first engine run.

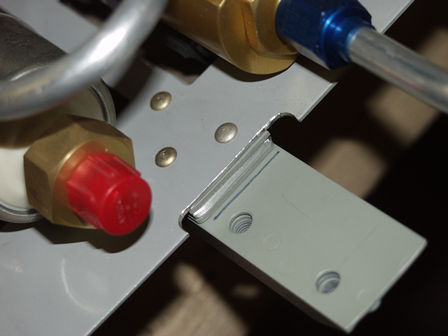

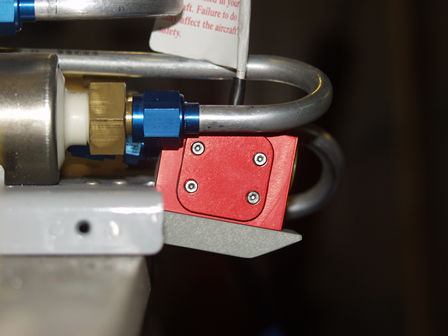

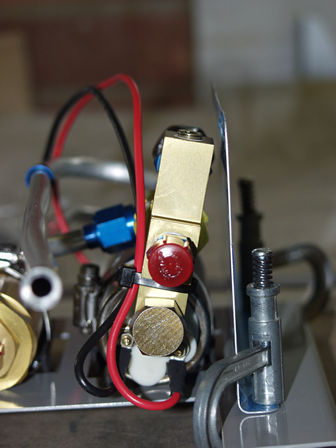

If you are fitting fuel injection to your engine you can use the

Precision high pressure fuel pump and filter. This is available

from Vans as a kit.

Here are some pictures of the pipes you need to bend - they may help you make sense of the Vans instructions and plans.

NOTE: I have added to fuel flow for my Advanced engine monitor - so the bends are NOT exactly as the Vans plans to allow the flow meter between the filter and pump.

I am using the andair fuel tap - it's far better than the Vans kit supplied tap (but still available from the Vans catalogue!).